Remember, Air conditioner refrigerant is toxic and can cause frostbite, so, please take the below-mentioned precautions before you begin with AC gas filling.

Safety measures:

- Use gloves

- Wear protective eyeglasses

Our recommendations:-

Gloves

3M CGM-GU Nitrile Rubber Comfort Grip Gloves

with shape memory characteristicsWith a nitrile palm coating over a breathable nylon stretch liner, the 3M Comfort Grip Glove CGM-GU is light, flexible and abrasion-resistant. Count on it for light- to medium-duty jobs that require precision handling, even in hot and sweaty conditions.

- VINAYAKAMART Nylon Shell Crinkle Finish Latex Coating Safety Working Supported Industrial Use Hand Gloves

- SAFEYURA® Cut Resistant Gloves Hand Protection Multipurpose

- Honeywell-2132651/M-Pk2 Black Pu Coated Polyester Knitted Glove

Eyeglasses

Honeywell A800

Safety GlassesUvex A800 Series provides ultra- lightweight protection and added comfort at a great value. Available in 2 lens coatings: HC and Uvextra AF (on clear and gray lenses). Uvex A800 Series has a 9-base PC wraparound frame, flexible and padded temples, and a non-slip nose bridge.

Equipment Required

- Vacuum Pump with 1-4 horsepower

- AC manifold gauge set

- Refrigerant

- And some patience (more on it later) ?

Procedure for AC gas filling

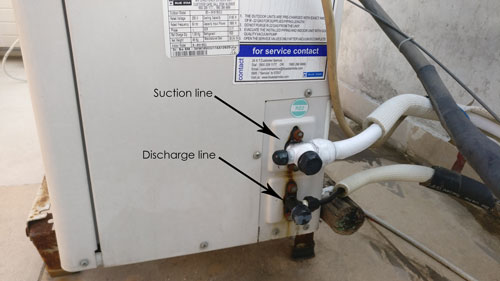

- Filling AC gas is actually an easy job with the right tools and safety gear. First, on the air conditioner locate the suction line(low side) and the discharge line (high side). These are located behind a window AC and in a split AC in the outdoor unit The suction line is located above the discharge line and is cool the touch.While the discharge line is warm to the touch. The suction line is used for recharging gas into the AC.

- Unscrew the bolt of the suction line as shown below. Loosen the screw inside with a Torx hex key(as shown in the picture below). This screw acts as a valve, it won’t let refrigerant flow in or out till it is closed. Thus, loosening this screw is important for filling AC gas.

- Then remove the bolt on the left and connect the blue hose of the AC manifold gauge to this port. Connect the yellow hose to the vacuum pump. Remove all the air from the system. This step is very important because any moisture inside the compressor will damage it.

- Now, make sure all the valves of the AC manifold gauge are closed. Then, connect the yellow hose to the refrigerant tank. Before opening the tank knob, loosen the yellow hose slightly at the manifold end. Then open the cylinder knob for 1 second and close it. This will remove all the air from inside the pipes. Now, again tighten the yellow hose.

- Now, open the low side knob of the manifold for 3-4 seconds and close it. Then turn ON the AC and wait till the compressor kicks in.

- Once the compressor starts, again open the low side valve of the manifold. Keep the valve opened for 4 seconds and close it for 2 seconds. Note where the pressure settles on the gauge once the valve is closed. Keep opening and closing the valve till the pressure settles between 60-70 PSI.

Note: The AC refrigerant gas is filled in small amounts at a time because releasing all the gas at once will damage the compressor.

- After reaching the 60-70 PSI range,

- Close the manifold valve

- Close the refrigerant tank knob

- Unscrew the blue hose from the suction line

- Unscrew the yellow hose from the refrigerant tank

Done!

Types of AC gases

Did you know that every air conditioner does not work with a common refrigerant? Following are some of the common refrigerants used in air conditioners today:

- R410A – commonly known as Puron (its brand name). R410A is used in all the latest air conditioners now. It is a hydro-fluorocarbon (HFC) and does not affect the ozone layer. R410A became the new standard for U.S. residential air conditioning systems back in 2015.

- R22 – commonly known as Freon (its brand name). It is a hydro-chlorofluorocarbon (HCFC), thus contributes in ozone layer depletion. R22 was discontinued for use in residential air conditioners due to their harmful effects on the environment.

Performance difference between R22 and R410A

R410A has better heat transfer efficiency, thus the AC unit has to do lesser work for the similar amount of cooling, which translates to a better life of the air conditioning unit. R410A works at a higher pressure than R22, so don’t fill an R22 compatible AC with R410A because the compressor will just…explode.

On a side note, R22 is has been phased out from use in residential air conditioners. These days, many manufacturers are providing conversion kits for older ACs to make them R410A compatible. While this a safe upgrade, but not reliable in the long run. Upgrading is also very expensive (almost half of the cost of a new AC). Thus, it is a better idea to buy a new R410A compatible air conditioner.

Reasons for AC gas Leakage

- Manufacturing defect: every manufacturing process isn’t 100% free of errors, even more so if humans are involved in putting together the unit. There are multiple joints and welds which could cause a leak if they’re not made with high precision. If there are manufacturing defects in the AC, leakage will occur during the initial stages of use and thus can be repaired under warranty.

- Incorrect installation: vital part of AC installation includes making flare nut connections and bending the copper pipes, which ironically are the most common areas of refrigerant leak. To avoid this, flare nuts should be sealed with teflon tape, and copper pipes should only be bent via a tube bender (copper pipes are soft, and easily develop sharp bends if the force applied on it is concentrated in a small area).

- Regular wear and tear: Air conditioners are pressurized units. With time the bolts and joints can become weak and develop a leak.

Now you know everything about AC gas refilling, the types of gases used, the precautions to take to avoid gas leakage in future! If you have any doubts, please feel free to comment in the section below.

If you’re a DIY person, we have some recommended tools and equipment for you:-

AmazonBasics Mechanic Socket Tool Kit Set With Case

Set of 201201-piece socket set combines most popular sockets, wrenches, and hex keys for easy accessibility. Also includes the most common screwdriver bits. Scroll down the page for a full list of included pieces.

Best Tool Kits-

- Bosch GSB 550 Mechanic Kit Professional

- iBELL IBL TD13-100, 650W Professional Tool Kit Pack of 115 with 6 Months Warranty

- STANLEY STMT82672-0-12 Chrome Compact Socket Set, 1/4″, Silver (37pcs)

- Grizzly 46 In 1 Pcs Tool Kit & Screwdriver and Socket Set

Multipurpose Multimeter

AstroAI Multimeter

Digital Multimeter with DC AC Voltmeter and Ohm Volt Amp TesterThis Multimeter is designed to troubleshoot a variety of automotive and household electrical problems safely and accurately

- Techtest Xl830l Pocket Digital Multimeter with Battery

- SCHOFIC Digital LCD Pocket Multi Meter/AC-DC Voltage/with Back Light (Yellow)

- R-tek 830L 3 Digit, 600 AC/DC Voltage Digital Multimeter with Back Support and Back Blue Light

- Unity Digital LCD Pocket Multi Meter/AC-DC Voltage/with Back Light (Yellow)

Loading recommendations...

I am from MACES Cooling Solutions and I am totally agree with your procedure and love the way you explained it.

Thank you for your instructions test grade calculator

Doing it yourself will make us feel more excited grade calculator

What a helpful essay! This page contains a wealth of information regarding the quordle that may help anyone launch a successful social media campaign.

I’m learning to become an air conditioner technician, your article have really helped me a lot.

Thanks

Thanks for the informative blog I have found your blog and https://www.allrefrigerants.com/ blog very interesting keep posting

How much time does R22 Gas Take to completely settele on 70 Psi in 1 Ton Split AC ?

Thanks for sharing! Your blog always contains informative material

Really explanative, nice job.

Nice post!! these tips may help me in the future. useful information

oh ya my means stuff

I really appreciated this quality work. Nice post!! these tips may help me in the future.

Please sir what alternative gas can we use to refill R32?

thanks for the very good information and genuine 5-star post shared by you.

R290, a highly refined grade of propane, is another option for filling or refilling refrigeration systems. Yes, it is flammable, but this not an issue with a properly sealed system, and if the building or vehicle wherein it is used should catch fire, the small amount of propane in a typical refrigeration loop won’t contribute much fuel. Propane is compatible with the lubricants used with R22 and R134a, so it generally does not cause problems swapping it for the old refrigerant. Moreover, it works well at lower pressure than R134a, so it is a good choice to extend compressor life. Unlike R134a, which produces deadly phosgene gas as it decomposes in a flame, R290 produces only carbon dioxide and water. This represents a significant safety improvement in motor vehicles suffering an engine compartment fire or a refrigerant leak that is ingesting by a running engine. Finally, R290 is not classified as an ozone-depleting gas, so it does not require an HVAC license to purchase and use.

Is there a sticker on the AC indicates the type of gas should be use?

What is the high side valve of the manifold gauge use for?

How much pressure required in Heavy equipment’s machine hvac. We are using R134A.

Contact Us if you are looking for ac gas refilling problem.

I have an AC of Toshiba it keeps leaking. The item is in warranty but i am thinking of changing the AC, What should i do?

useful information. but gas leakage problem may exists if not done properly. technicians have to ensure the leakage is checked before leaving