Have you ever experienced your AC not cooling enough or not cooling at all? So you call a professional to diagnose the problem only to tell you that the cooling coil needs to be replaced completely? Well, when the cooling coil of ACs get corroded, they might develop leaks and cracks. As a result, the refrigerant flowing through them leaks out and the AC cannot maintain compressed air in the coils anymore. No compressed air means no cooling.

Corrosion happens overtime no matter which type of materials you are using. But it does help a lot to choose the right type of cooling coil (copper vs aluminium) when it comes to buying ACs. Copper is much more durable than aluminium but costs more.

Now this article might get a little technical when it comes to the techniques used to prevent corrosion or to say making the right choice or technology when it comes to cooling coil. For regular home AC buyers, just ask your retailer and they should be able to guide you depending upon your requirements. The rule of thumb is to go ahead with Copper based cooling coils.

The main thing to consider when it comes to protecting or maintaining the cooling coils (which is a collective name we use for two separate units of coils namely condenser coils and evaporator coils) is to protect the coils from humidity and moisture and certain atmospheric elements like chemicals or particles in the air (depending upon the area you are living in). The best way of doing so is to paint something with anti-corrosive paints to prevent it from corroding.

The Blue Fin Condenser

For most of you, a regular AC with a copper coil should last several years without any problem provided you regularly maintain your AC and clean it often. However, for those who are living near coastal areas where the salt content in the air is very high, certain brands use “Blue Fin Condenser” which is very effective in protecting the condenser coils from humidity.

Micro Channel Aluminium Condenser

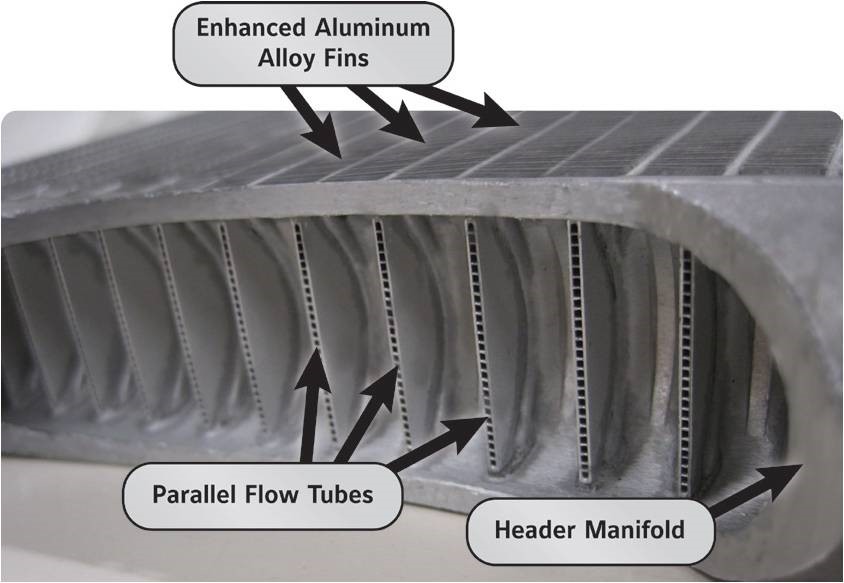

The use of micro channel condenser coils is also quite common in order to negate the effects of corrosion. So for those who want to make a considerable investment in AC, especially for organizations etc. it’s better to evaluate and do your homework when it comes to understanding these technicalities as well. In a micro channel condenser, the refrigerant is transferred through micro channels made of highly malleable aluminium fins.

This micro channel type of cooling coil makes use of aluminium (because of it malleability and flexibility) to protect against galvanic corrosion (caused by salt contents). This type of AC system works well for people residing in the coastal areas where you have a high concentration of salt in the air.

Loading recommendations...

If you enjoy online fun, please visit our website, where many popular and new games are often updated Retro games for free.

How to protect your A/C from Rust & Corrosion

We can offer a corrosion protection for your HVACR needs, including Air Conditioning , Refrigeration , Agricultural and Coastal units.

HVAC units and Generators in water treatment plants.

We offer onsite coating along with inhouse coating , we coat A/C coils , Pool Heaters, radiators , generators and equipment

Visit our website at http://www.Bronz-Glow.com

WE help cure Dirty Sock Syndrome

It’s better for both your HVAC system and your wallet to prevent coil corrosion in the first place.

What about sacrificial anodes like the Corrosion Grenade. From what I’ve read, they need to be installed when the units are new and inspected annually then replaced as needed. I had a 6 year old Goodman heat pump at a property 2 blocks from the beach. While mowing one day I noticed grey stuff around the base. It was the fins falling off due to corrosion.